Introduction

Test Preparation and Results

Numerical Modelling

Generation of Realistic Aggregates

Numerical Modelling Method

Interpretation of the Measured and Computed Results

Stress-strain Relationship

Effect of Calcite Content

Effect of the Particle Size

Conclusions

Introduction

Bio-cementation based on microbial-induced calcite precipitation (MICP) has recently emerged as an environmentally friendly alternative technique for the ground improvement of the granular soils. Experimental studies on MICP cemented soil have focused on the stabilisation of fine sands and regular granular particles (DeJong et al., 2006, DeJong et al., 2010; Whiffin et al., 2007; Ivanov and Chu, 2008; van Paassen et al., 2010; Dvorkin et al., 1994; Shashank et al., 2016; Al-Salloum et al., 2017; Chen et al., 2017; Tan et al., 2018; Oshiro and Matsubara, 2018; Wu et al., 2019b), and only limited studies have been reported for stabilisation of coarse aggregates (e.g. irregular coarse particles). In fact, the cemented aggregates of solid particles are essential ingredient of many industrial products such as sandstones and conglomerates (Mahawish et al., 2016), mortars, concrete, grouted soils (Cheng and Cord-Ruwisch, 2014). The common denominator of all these materials are the assembly composed by a dense granular and a paste partially filling the pore space (Chen and Indraratna, 2014; Chen et al., 2015). It has been described as intermediate materials between particle-reinforced composites and cohesionless granular media. The intermediate material has been determined as one of the major factors controlling the stabilisation of cemented coarse aggregates as most of the cracks are initializing in the intermediate zone by experimental observations (Topin et al., 2007). The physical properties of the intermediate materials could be represented by the interface debonding, the matrix deformation, etc.

The mechanical properties of the bio-cemented coarse rock aggregates also depend on its intermediate materials. However, the physical properties of the intermediate materials in such cases are more complex as the surface adhesion among the bio-cemented coarse aggregates depends not only on the aggregates surface but also on the bio-cemented bonds properties (Mahawish et al., 2016; Fan et al., 2017). It causes some difficulties to quantify the contribution from intermediate materials on the mechanical properties of the bio-cemented aggregates from experiments alone. In addition, the pore space might not be fully filled by the calcite materials generated by a random bio-cementation process. The bare contacts behave as defects in the cemented aggregates, leading to a reduced stiffness or/and strength in both tension and compression. Hence, the physical property of the intermediate material is dramatically controlled by the volumes of the CaCO3 and the remaining void among particles, and further influences the mechanical behaviour of the bio-cemented aggregates.

Numerical models have been developed to simulate the mechanical behaviour of the assemble granular aggregates or particle-reinforced composites. Discrete element method (DEM) is a useful approach for the simulation of granular materials composed of rigid particles (Topin et al., 2007; Chen et al., 2017; Shang et al., 2017; Lopera Perez et al., 2017; Wu et al., 2017; Ma et al., 2017). In this paper, the three-dimensional particle flow code (PFC3D), a commercial particle-based DEM developed by Itasca (Itasca Consulting Group, Inc., 2015), was employed for a detailed analysis of the mechanical behaviour of the bio-cemented aggregates under uniaxial compressive loading. The numerical models were first verified by comparing with experimental works. The relationships of UCS and elastic modulus with the cohesion and stiffness of MICP bond were further investigated in both experimental and numerical studies.

Test Preparation and Results

In this study, the bacterial suspension and cementation solution are the same with the references (Wu et al., 2019a). Three groups of assembled rock aggregates specimens (i.e., D1, D2 and D3) were used in this study (see Table 1). For each group, 5 columns were prepared with different calcite content. The dry aggregates were packed into a polyvinyl chloride (PVC) column (160 mm in height and 55 mm in inner diameter) under a continuous vibration to reach the relative uniform density distribution. For the sample treatment, we followed the detailed procedure provided in reference (Wu et al., 2019a).

Table 1. Experimental settings of three group of assembled aggregates

The test results indicate that both grain size and CaCO3 contents have significant effects on the mechanical behaviour of bio-cemented aggregates especially for fine-sized aggregates. As the CaCO3 crystals are the main intermediate materials, their contributions on the strength of assembled aggregates are presented in the CaCO3 contents. Based on the test results, the UCS of the bio-cemented aggregates increases with the increase of CaCO3 contents for all three grain sizes. However, the degrees of increasing are not the same. The finer the aggregates the higher the increment in UCS given the same calcite increment. In terms of grain size, the test results suggested that UCS of the finer aggregates is larger than that of the coarse groups given the same CaCO3 content.

Numerical Modelling

Generation of Realistic Aggregates

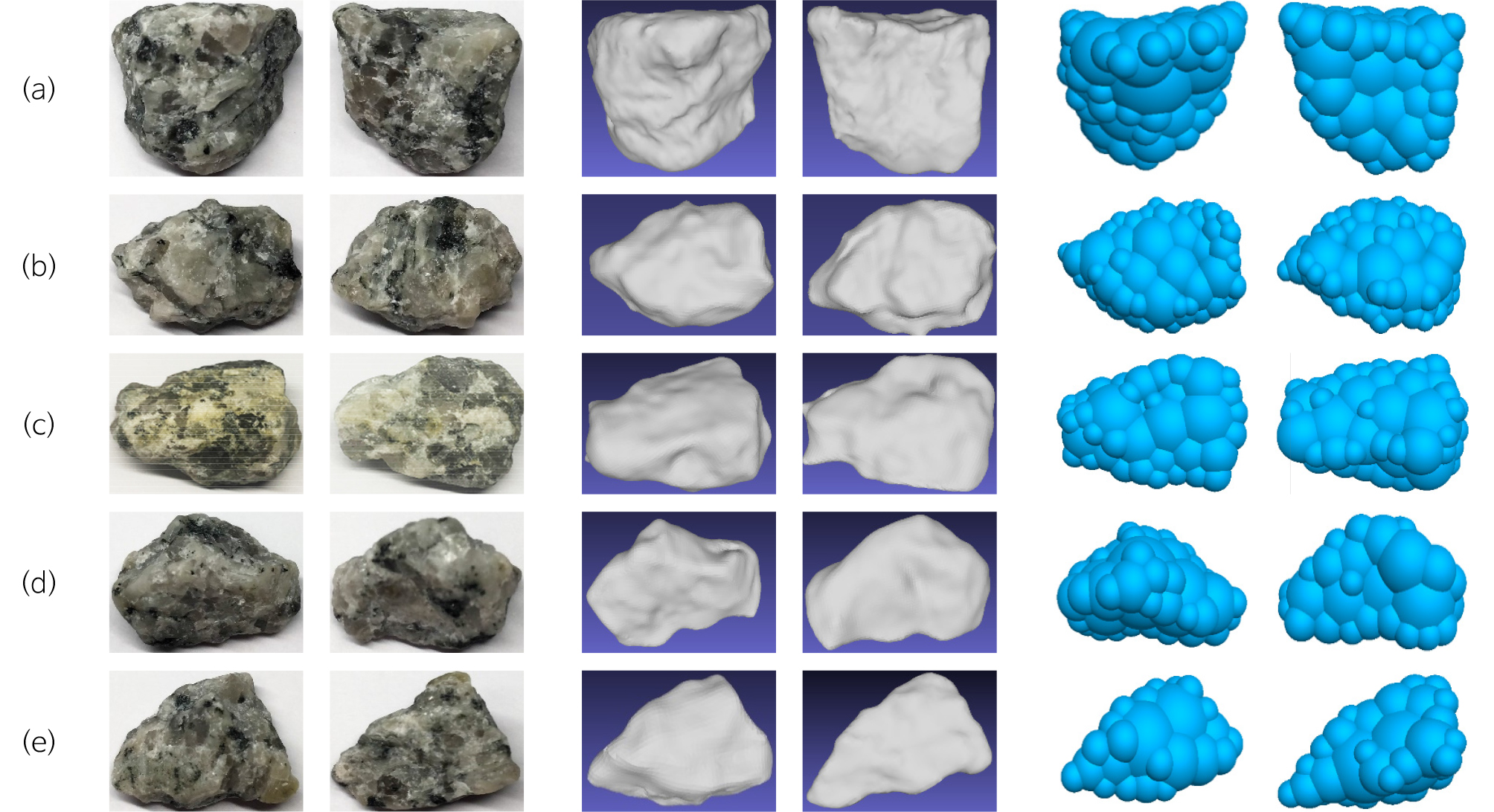

Based on 3D scanning and 3D printing technology (Wei et al., 2018), the realistic aggregates particles were incorporated into DEM model for granular column collapse simulation. Five typical aggregates were used to simulate the mechanical property of the bio-cemented aggregates. The profiles of them are shown in Fig. 1. To validate this method, the virtual aggregates assemblies with the mixed types of five aggregates were generated and the numerical test results were compared with laboratory test results, whose 3D printing and shape parameters were compared with those of real gravel particles.

Fig. 1.

Generation of the aggregate. Left column: photos of the five typical rock aggregates; middle column: 3D scanning photos of the aggregates; right column: clumped particles to represent the rock aggregates in the DEM model. The photos of granite aggregates particles used in this test. Photos from two perspectives were provided in these figures.

Numerical Modelling Method

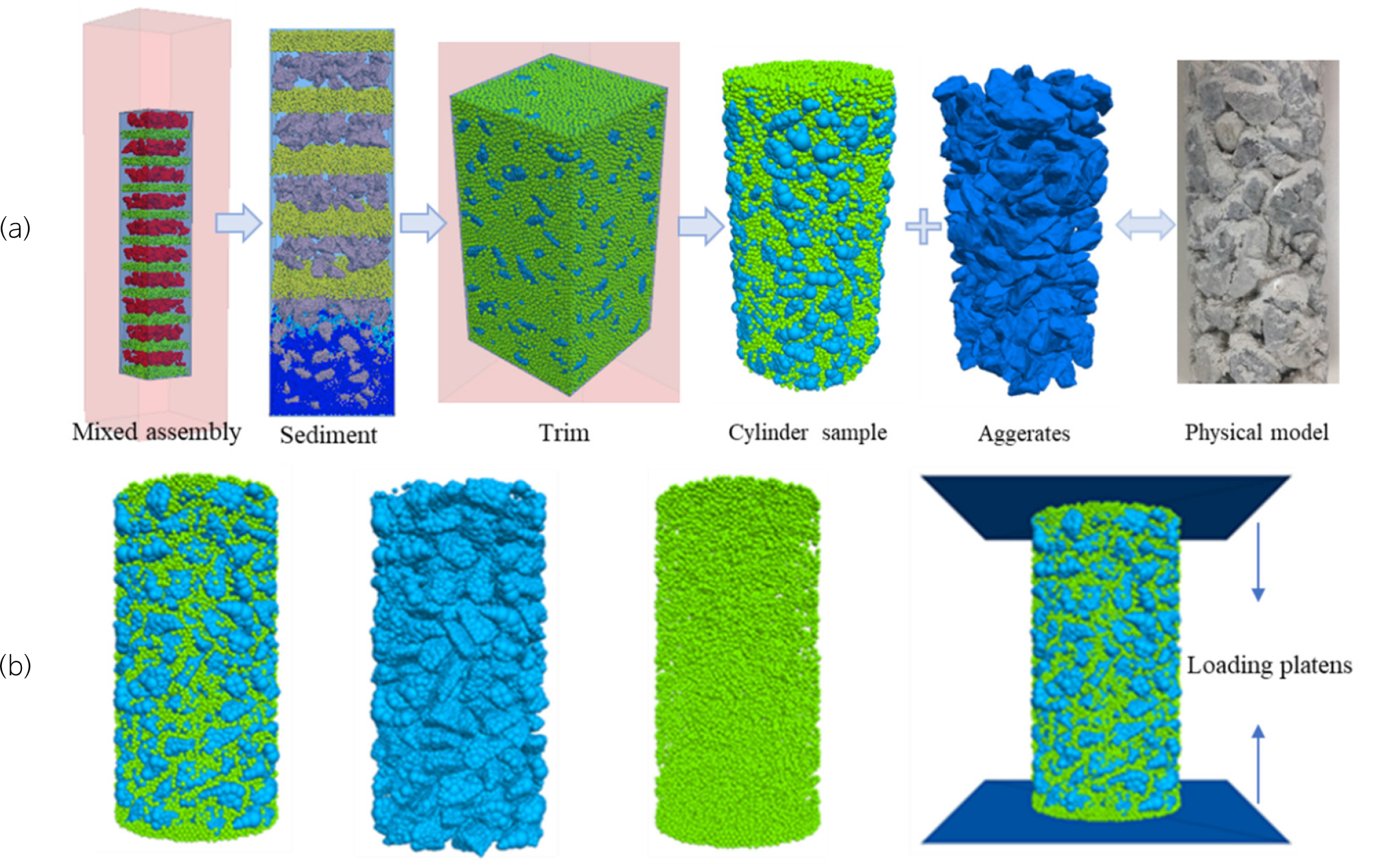

Generation process of the PFC3D model to represent the aggregate samples with calcite for three sizes of aggregates samples were shown in Fig. 2a. The uniaxial compression tests in PFC3D were conducted through moving the top and bottom platens towards each other. A downwards displacement speed of 0.1 mm/s is applied on the top platen and upwards displacement speed of 0.1 mm/s is applied on the bottom platen to simulate the loading process. The parameters used in the numerical model are shown in Table 2.

Table 2. Micro-parameters adopted to model the aggregates

We modeled the complex shapes of aggregates in PFC3D by clump logic, which is a method to form irregular particles by connecting and overlapping a number of spheres of different sizes, and by assigning the corresponding radii and coordinates (Itasca Consulting Group, Inc., 2015). In this way, the clump behaves like a rigid body in which the internal contacts are ignored. Different from a group of particles that are bonded together, a clump acts as a rigid body (with a deformable boundary) that will not break apart, regardless of the forces acting on it. This model is reasonable to represent the MICP bond (calcite) as most failure occur in the CaCO3 and the aggregates stay intact during the whole testing process. To model typical aggregate shapes, five aggregates were selected as can be found in the left column of Fig. 1. These typical aggregates shapes were mimicked by assembling a number of pebbles. To do this, the clump templates were built through the digital image processing (see the middle column of Fig. 1). A clump template serves as a basis for creating clumps in the model with the same shape as the clump template. After that, groups of pebbles were created and modified following the clump logic. Details about the micro-parameters adopted to generate the aggregates are provided in Table 2. These parameters inherit from the study of Potyondy and Cundall (2004).

The aggregates mixed with the small particles (to represent the CaCO3) are then allowed to settle in the box under gravity. Different calcite content was modeled in this test with different number of small particles but same number of aggregates for each type of sample. The mixed assemblies were then allowed to move in the box until the equilibrium was reached. Micro-parameters are then assigned to the contacts between the small particles and those between the aggregates and the small particle. After that, the assemblies were trimmed to be cuboid and then to be cylinder shape, to mimic the samples tested in the laboratory (see Fig. 2a). Micro-parameters defining the bonds are calibrated to reproduce the stress-strain curve of the physical model subjected to uniaxial compression test. This process was achieved through a set of trial and error tests.

To achieve both accuracy and efficiency, we used the same morphologies of the digital images as illustrated in Fig. 1 and only modified the size of them with the ratio of 0.7 for medium size of particle and 0.4 for small size of particle. DEM samples established following the aforementioned procedures are listed in Fig. 2b~2d. With these models, we conducted a set of parametric studies with the objectives to evaluate the influence of particle size and content of CaCO3.

Interpretation of the Measured and Computed Results

Stress-strain Relationship

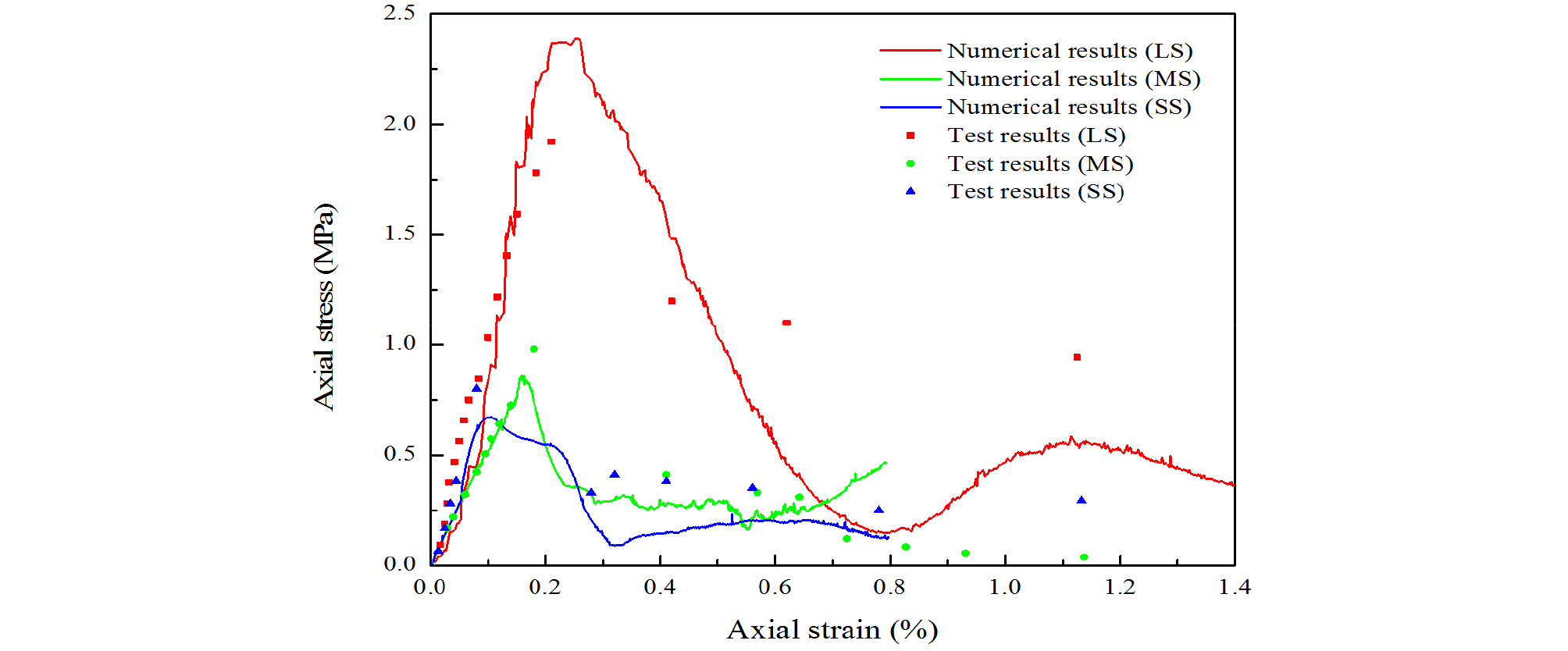

The numerical results in terms of the stress-strain curves are shown in Fig. 3. The curves show good agreements with the experimental results before the peak strengths were achieved. During this stage, the stresses increase gradually with the accumulate strains. After the peaks, the specimens still have some strengths which are associated with strain-softening behaviour. Even the post-peak curves show some degree of scatter with test results, they can catch the variations of soften/brittle failures after peak values. Thus, the DEM models are suitable to simulate the current problem.

Effect of Calcite Content

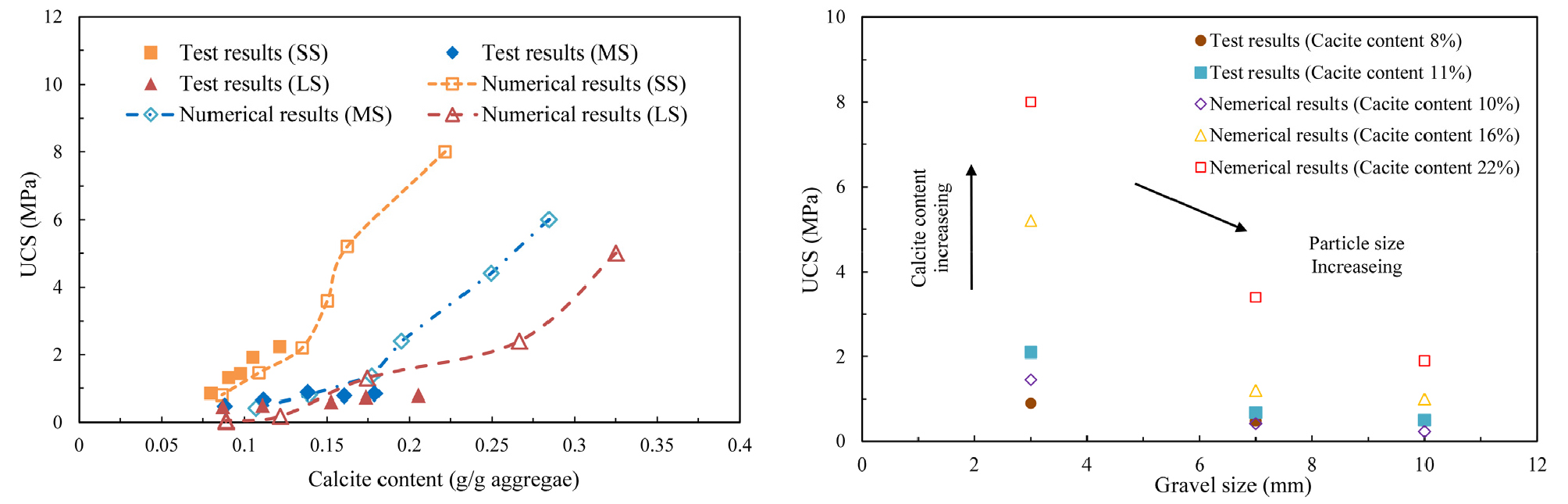

The variation of UCS of bio-cemented samples with CaCO3 content was shown in Fig. 4a. It can be seen that, the UCS from numerical results increase with the increase of CaCO3 content for all samples which are in line with the test results for all three sizes of aggregate samples. The SS (small particle) samples show the highest value of slope, the MS (medium particle) samples show the medium value and the LS (large particle) samples show the least value. The lower UCS for the coarser aggregates (MS and LS) samples might be because for the coarser aggregate samples the produced CaCO3 crystals would largely act as pore-filling materials or coating on the surface of the gravel rather than on the contact point of the aggregates due to the larger void size. The CaCO3 contributes to the cementation and strength improvement (Cheng et al., 2013; Wu et al., 2019a). Similar results were reported by Mahawish et al. (2016) that as the coarser materials require a high amount of cementitious material to gain an acceptable strength, very often they are considered not suitable for treatment by bio-grout process as they need higher number of biochemical treatment cycles. The numerical results also confirmed the statements from these researchers. Different failure patterns can be noted from the samples with various calcite contents. In general, the failure mode transform from localized spalling from the lateral surface to the macroscopic shear fractures crossing the whole sample with the increment of calcite content.

Effect of the Particle Size

The variation of UCS against the particle size is shown in Fig. 4b. As is stated before, with the same calcite content, the SS samples show the highest value of the UCS and the MS and LS show the lower value. These results show that the particles size shows high influence on UCS of the aggregates samples. This finding is in line with previous observations (Cheng et al., 2013; Mahawish et al., 2016) that with the same amount of CaCO3 precipitates, the UCS values of the fine sand were greater than that of the coarse sand. This is because smaller particle size provides greater number of contact points, which contributes to more effective crystals formation thus higher bonding strength (Ismail et al., 2002). Large aggregate columns present larger void size and lower contact point which will give rise to a lower number of bridging of aggregates. The numerical results show the same trend with test results that the UCS decrease with increase in particles size.

Conclusions

The bio-cementation based on MICP has shown its potential in geotechnical applications. In this paper, experimental results highlighted that both the size of aggregates and the CaCO3 content could influence the mechanical behaviour of bio-cemented rock aggregates. Three-dimensional DEM simulations have been carried out to examine the mechanical mechanism of bio-cemented aggregates. The failure mechanism of the bio-cemented aggregates was investigated by comparing the numerical results with the test results in terms of the stress-strain curves and the crack propagations as the breaking bonds. The results agreed with the previous studies that the UCS would increase with the increase of CaCO3 content. The parameters of the PFC model of bio-grouted aggregates with different grain size and calcite content were proposed for further application in field. The results indicate that the modelling approach proposed in this study is reliable for simulating and thus can be used for further investigation of micro-mechanisms at particle scale.