Introduction

Geological Framework of Research Area

Nawakot Complex

Kathmandu Complex

Methodology

Tests for Physical Properties

Mechanical Properties

Durability Test

Result and Discussion

Description and Classification of Samples

Physical Properties

Mechanical Properties

Durability

Conclusions

Introduction

The strength and durability of rocks are critical factors in determining their suitability for various applications. The assessment of both strength and durability is crucial in distinguishing between superior and inferior-quality construction materials (Ahmad et al., 2017). Strength is typically assessed using measures such as the Point-load Strength Index (PLSI), Aggregate Crushing Value (ACV), and Aggregate Impact Value (AIV), which respectively evaluate the resistance of rocks to crushing and impact. Durability, on the other hand, refers to the long-term resistance of rocks to weathering, and abrasion, which can be evaluated through tests such as the Slake Durability Index (SDI), Sulphate Soundness Value (SSV), and Los Angeles Abrasion Value (LAAV) (Gökceoğlu et al., 2000; Erguler and Ulusay, 2009; Gautam and Shakoor, 2013).

Numerous researchers have examined the physical and mechanical characteristics of rocks in the Lesser Himalaya and Sub-Himalaya regions to explore their potential use as aggregates (example: Tamrakar et al., 2003; Dhakal et al., 2006; Maharjan and Tamrakar, 2007; Khanal and Tamrakar, 2009). Recently, a study by Gupta and Sharma (2012) conducted on quartzites from the northwest Himalaya also shows that there is a strong correlation between texture and rock strength. Similarly, quartzites are recognized as one of the strongest and most durable rock types (Maharjan and Tamrakar, 2007; Bista and Tamrakar, 2015). Regarding the Nepal Himalaya, the Central Nepal Himalaya is rich in quartzite beds of various litho-units, namely Fagfog Quartzite, Dunga Quartzite, Pandrang Quartzite, and Chisapani Quartzite (Stöcklin, 1980). In this regards the present study primarily focuses on investigating the strength and durability characteristics of those quartzites units and found that the Chisapani Quartzite is generally considered to be the best of the four quartzite units within the Lesser Himalaya. It has the highest UCS, AIV, and ACV values, which means that it is the strongest and most wear-resistant of the four. It also has a relatively low WA value, which means that it is not as susceptible to water damage. Whereas, the Fagfog Quartzite is also a good choice, as it has high UCS and AIV values but it has it is more susceptible for the weather as it has higher WA value.

Geological Framework of Research Area

The research area is situated in the Central Nepal Himalaya, specifically within the Lesser Himalaya (Fig. 1a). The key geological and tectonic units in the Lesser Himalaya are the Kathmandu Complex and the Nawakot Complex. The Nawakot Complex can be further subdivided into the Upper Nawakot Group and the Lower Nawakot Group, while the Kathmandu Complex is divided into the Phulchawki Group and the Bhimphedi Group (Stöcklin and Bhattarai, 1977). In terms of stratigraphy, the Nawakot and the Kathmandu Complexes serve as distinctive units in the Lesser Himalaya (Stöcklin and Bhattarai, 1977). The Lesser Himalaya is positioned between the Sub Himalaya and Higher Himalaya, with the Main Boundary Thrust (MBT) marking its southern boundary and the Main Central Thrust (MCT) demarcating its northern limit.

Fig. 1.

a) Geological map of Nepal (modified after DMG, 2020) with the study area marked by the rectangle; b-c) Regional geological map of the study area, modified after Stöcklin and Bhattarai (1977). kn = Kuncha Formation, fg = Fagfog Quartzite, da = Dandagaon Phyllite, np = Nourpur Formation, dh = Dhading Dolomite, F1 to F15 are sample sites.

Nawakot Complex

The Nawakot complex is mostly comprised of low-grade metasedimentary rocks (Table 1). This unit is further sub divided as the Lower Nawakot Group and the Upper Nawakot Group (Stöcklin and Bhattarai, 1977).

Table 1.

The Himalayan units in Central Nepal (modified Stöcklin and Bhattarai, 1977)

Lower Nawakot Group

Lower Nawakot Group comprises the Kuncha Formation, Fagfog Quartzite, Dandagaon Phyllite, Nourple Formation and the Dhading Dolomites (Table 1).

Kuncha Formation

The Kuncha Formation is the oldest unit of the Lesser Himalaya. This formation consists of monotonous lithology containing greenish-grey phyllite, quarzitic phyllite, phyllitic metasandstone, gritstone, micro-conglomerate, and black schist occasionally with bands of amphibolite (Pecher, 1978; Stöcklin, 1980; Sharma and Kizaki, 1989).

Fagfog Quartzite

The Fagfog Quartzite consists of fine- to medium-grained, milky orthoquartzite intercalated with fine-grained phyllite, and greenish-grey schist. The thickness of this quartzite unit is approximately 350 m. The sedimentary structures such as ripple marks, graded and cross beds show the normal sequence (Pecher, 1978; Stöcklin, 1980; Arita, 1983; Sakai, 1985; Sharma and Kizaki, 1989).

Dandagaon Phyllite

The Dangagaon Phyllite consists of fine-grained, dark, blue, and greenish-grey phyllite, intercalated with fine-grained quartzite. Due to the presence of carbonaceous materials, the phyllite of this formation is distinctly darker than the Kuncha Formation (Arita, 1983). Calcareous phyllite shows the thin laminae with the greenish-grey phyllite. Crenulation cleavages are well developed in the phyllite showing polyphase deformations along the Malekhu-Dhadingbensi road section (Arita, 1983).

Nourpul Formation

The Nourpul Formation consists of fine-grained, multi-variated quartzite intercalated with greenish-grey phyllite and schist. A few meters thick calcareous quartzite is also intercalated within the thin layers of black slate. Cross beds, graded beds, ripple marks, parallel laminations, and mud cracks are well preserved in this formation (Rai, 2011). These sedimentary structures show the overturned beds. The presence of cross-beds, and ripple marks indicate that the sedimentary environment of this formation was shallow marine whereas the presence of the mud cracks show an arial condition (Sakai, 1985).

Dhading Dolomite

The Dhading Dolomite consists of well-stratified, finely crystalline, massive, fractured, grayish blue dolomite characterized by stromatolite, intercalated with fine-grained shale observed the stromatolite in association with Lower Paleozoic algae and echinoderms along the Trishuli Valley (26 km WSW of Dhadingbensi) and l.5 km south of Dhadingbensi. Stöcklin and Bhattarai (1977) & Stöcklin (1980) observed erosional surface (unconformity) marked by abrupt lithological change with traces of laterization between the Dhading Dolomite and the Benighat Slate along the lower Burhi Gandaki valley, a tributary of the Trishuli River.

Upper Nawakot Group

Benighat Slate

The Benighat Slate consists of fine-grained, more or less carbonaceous slate, grey phyllite intercalated with carbonate rocks and calcareous quartzite. This formation along the Malekhu-Thopal Khola section is found to be folded with development of the metric scale of anticline and syncline (Rai, 2011).

Malekhu Limestone

The Malekhu Limestone consists of thin-platy, well-stratified, fine-grained, dense, yellowish-grey Siliceous limestone, dark and grey color dolomitic limestone intercalated with fine-grained, grey shale or phyllite. Parallel laminations are well preserved. Stromatolites are absent.

Robang Formation

The Robang Formation is mainly composed of phyllite with an interrelation of quartzites. In the upper part, the quartzites predominate.

Dunga Quartzite

The Dunga Quartzite, a member of Robang Formation consists of fine-grained, greenish-grey, greyish-white phyllite associated with grey quartzite. A few meters thick of metagabbro or metadiabasic rocks are intercalated within the phyllite and quartzite.

Kathmandu Complex

Bhimphedi Group

The Precambrian Bhimphedi Group consisting of relatively high-grade metasediments shows steady decrease in the metamorphic grade from garnet schist at the bottom to the sericite-chlorite grade on the top. Metamorphic grade is relatively high along the Mahabharat Thrust (MT). The total thickness of the Bhimphedi Group is about 10 km. The group consists of six formations, which are as follows from bottom to top.

Raduwa Formation

It is the oldest and lowermost unit of the Bhimphedi Group and consists of coarsely crystalline garnetiferous mica schist with quartzitic intercalations. The Raduwa Formation is separated by the MT from underlying Nawakot Group. The mica schist is dark greenish grey to light grey color, containing characteristic real garnet which occurs in great abundance, sometimes crystal up to 1 cm in diameter. Amphibole and pyroxene are common mineral associations. Thickness is 1,000 m and age of Precambrian.

Bhainsedobhan Marble

The Bhainsedobhan Marble overlies the Raduwa Formation with a transitional contact. It is composed of coarsely crystalline grey-white saccroidal marble consisting of economic minerals like pyrite (FeS2). Some partings and intercalations of biotite-garnet schist are also common. The thickness is 800 m.

Kalitar Formation

The Kalitar Formation is about 2,000 m thick, overlying the Bhainsedobhan Marble. This formation is characterized by the presence of greenish-grey coarse-grained mica schist with garnet at the lower part. Biotite is the predominated mineral whereas sillimanite, kyanite, sericite, and chlorite are also present. Towards the upper section, the grain starts to be finer, and also garnet size decreased. This unit consists of three members: Bhimsen Dolomite, Pandrang Quartzite and Jurikhet Conglomerate (Stöcklin, 1980). The Pandrang Quartzite member, a thick intercalation of orthoquartzite about 200 m above the base of the formation.

Chisapani Quartzite

The Chisapani Quartzite is 400 m thick and dominated by white or pale-green, fine-grained, clean quartzite with fine partings of sericite phyllite. It is fine-grained thin to thick-bedded quartzite showing strong cross-bedding and ripple marks (Stöcklin, 1980). The presence of cross-bedding in the Chisapani Quartzite indicates that the sediments were deposited under a shallow water environment. The Chisapani Quartzite overlies the Kalitar Formation with transitional contact.

Kulikhani Formation

The Kulikhani Formation overlies the Chisapani Quartzite with a transitional contact. At the contact point of Kulikhani and Chisapani, it consists of garnet bearing schists, metasandstone, micaceous quartzite of dark and light green colour. Fine-grained biotite-rich schist is also common. The presence of augen gneiss and biotite dominant schist is common. Isoclinal folds, micro-folds and drag folds are distinct in this formation.

Markhu Formation

This formation overlies the Kulikhani Formation with a transitional contact. The Markhu Formation has mixed lithology of schist, quartzite and marble in varying proportions. The dominant one is medium to coarse-grained, white to pink marble with intercalation of dark, fine-grained biotite schist and quartzite. The thickness of the Markhu Formation is about 1,000 m and has transitional contact with overlying the Tistung Formation.

Methodology

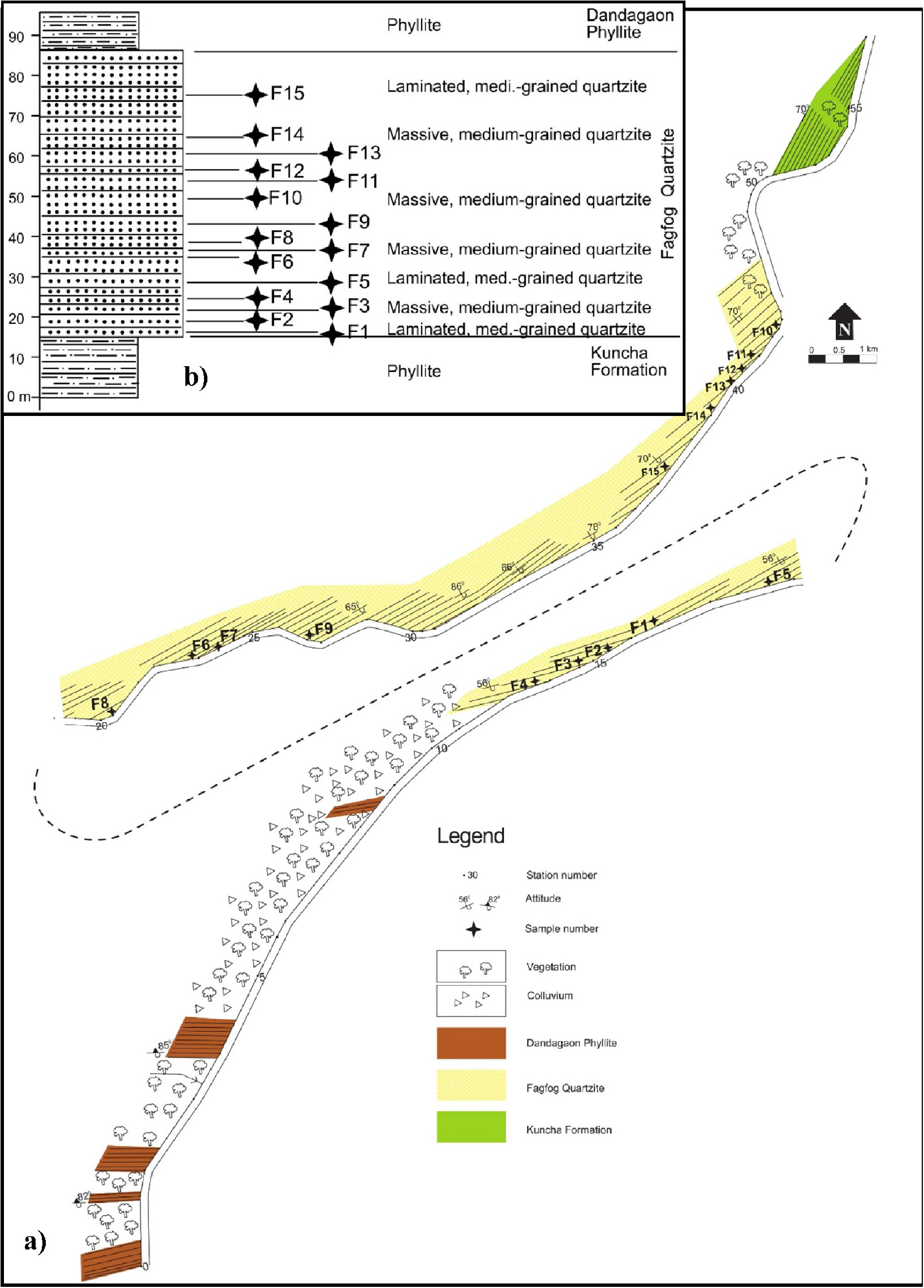

Selective samples of quartzites were collected as grab samples from various quartzite formations in the study area. These formations include the Fagfog Quartzite in the Malekhu to Thopal Khola Section (Fig. 1c) the Dunga Quartzite, the Pandrang Quartzite, and the Chisapani Quartzite in the Hetauda to Bhimphedi section (Fig. 1b). The sampling horizons, which provide information about the sampling location as well as the texture and structure of the rocks, were carefully noted during the sampling process.

Subsequently, the collected samples were taken to the material testing laboratory for further analysis at Central Department of Geology, Tribhuvan University, Kirtipur Nepal. Adequate quantities of each sample were prepared for the desired tests, which encompassed assessments of physical properties, strength, and durability. These tests were conducted to gain a comprehensive understanding of the quartzite samples’ characteristics and behavior.

Tests for Physical Properties

Shape Indices

Shape indices are attributed by flakiness index (FI) and elongation index (EI). Both FI and EI were determined following (BS, 1989) and (BS, 1990). FI was determined for 50 mm down to 37.5 mm and 37.5 mm down to 25 mm aggregates using a thickness gauge in which aperture size is 0.6 times the average of passing and retained sizes of aggregate to be tested. The following equation was used to compute FI:

where, X denotes weight of the fraction passing through the thickness gauge and W denotes the weight of the original sample on the corresponding sieve size.

The elongation index was determined by separating aggregates, which fail to pass through an elongation gauge. Aggregate particles are classified as elongate when they have a length (greatest dimension) of more than 1.8 of their mean sieve size. EI was calculated using the following equation:

where, Y denotes the weight of the fractions retained on the length gauge and W denotes the weight of the original sample retained as the corresponding sieve.

Specific Gravity, Density and Water Absorption

The laboratory procedures for specific gravity and water absorption were followed according to (ASTM C127, 2007, 2011). The test sample was oven-dried at constant mass at a temperature of 110 ± 5°C. The oven dry (OD) mass of sample was recorded. Subsequently, the sample was immersed in water at room temperature for 24 hr. Then it was removed and soaked by a moist cloth until all visible films of water were removed. At this stage, the saturated surface dry (SSD) mass of the sample was recorded. The SSD sample was then immersed in water removing all entrapped air by shaking the container when immersed. The apparent mass of the sample was measured in water. The following equations were used to compute, the specific gravity of the oven-dried sample (GOD), density of the oven-dried sample (DOD) and water absorption (WA):

where, A is the mass of the oven-dried test sample in air (in grams), B is the mass of saturated- surface-dry test sample in air (grams), and C is the apparent mass of the saturated test sample in water (grams).

Bulk Density

When aggregates are packed in a given volume of space, the volume of space not only contains aggregates but also void among particles. Therefore, bulk density takes into account both aggregates and void spaces in a given volume. It is also a measure of how well-packed the aggregates are in the given space. The bulk density of aggregate was determined (ASTM C29M-97, 2006) by rodding the ballast in a measure. The dry bulk density for rodding was calculated using the following relation:

where, G is the oven-dry mass of the sample plus the measure (kg), T is mass of the measure (kg), and V is the volume of the measure (m3).

Mechanical Properties

Point Load Strength Index Test

The point load strength Index (PLSI) test is intended as an index test for the strength classification of rock material (Broch and Franklin, 1972). Irregular lumps with their width and thickness measured and tabulated, were used in this test following the procedure (ASTM D5731, 2002). Irregular lumps were loaded normal to the stratification, and the breakage load was recorded in KN. The PLSI that is denoted by the symbol Is was calculated using the following equation:

where, P is a failure load (KN), and De is equivalent core diameter (m).

The equivalent core diameter is found out using the following expression:

where, A is the minimum cross-sectional area of a plane through the platen contact points. The A was obtained from the products of average width and average thickness of the lump measured at least at two lines. The standard point load strength index, Is(50) was obtained by the product of the size correction factor and point load strength index, Is, using the following expression:

For classification of strength of intact rocks, uniaxial compressive strength (UCS) was calculated applying the following relation:

Aggregate Impact Test

The aggregate test sample of size between 12.5 mm and 9.5 mm and weight of about 500 g was prepared according to (BS, 1990) and was filled in a cylindrical holder, one-third at a time, and tamped 25 times with a tamping rod. The test sample was then fixed in position at the base of the impact machine. The test sample was subjected to a total of 15 blows by the 14 Kg weight of hammer, each being delivered at an interval of not less than one second. The crushed aggregate was then removed and sieved on the 2.36 mm sieve. AIV was then calculated using the following expression:

where, M1 is the initial weight of the aggregate sample, and M2 is the weight of aggregate retained on 2.36-mm sieve.

Aggregate Crushing Test

The aggregate crushing value (ACV) provides a relative measure of resistance to crushing under a gradually applied compressive load. It was determined after (BS, 1990). About 3 kg of a sample of aggregate between 12.5 mm and 9.5 mm were put in a cylindrical holder at three stages slightly tamping 25 times at each stage. The cylinder with the test sample and plunger in position was placed on a compression testing machine. The load was applied in such a way as to achieve 400 kN load at 15 minutes. The crushed aggregate including the crushed portion was removed from the cylinder and was sieved on a 2.36-mm sieve. The ACV was calculated by using the following expression:

where, W1 = 3 kg is the initial weight of the dry sample, W2 is the weight of the aggregate retained on a 2.36 mm sieve.

Durability Test

Slake Durability Test

The durability of rocks against cyclic wetting in water and drying is measured by the Slake Durability Index (SDI). (ASTM D4644, 2008) was followed to carry out SDI test to report standard SDI at second cycles, Id2. Furthermore, three more cycles were added to see the deterioration behavior of samples. Therefore, in total of five cycle test was adopted. Initially, the sample fragments were weighed and dried in the oven for 16 hours and allowed to cool at room temperature for 20 minutes and weighed again. Thus, the natural water content was calculated using the following expression:

where, W is the percentage of water content, A is the mass of the sample at natural moisture content (g), and B is the mass of the oven-dried sample before the first cycle (g).

The lump test sample inserted in the drum was rotated at 20 rpm for 10 minutes. Afterward, the test samples were removed from the drum to dry in the oven for 16 hours at 105°C. After cooling, the sample was weighed to obtain the oven-dried mass for the second cycle. Again, the cycle was repeated to measure the weight of the sample to obtain a final mass. The tested samples were retained to evaluate disintegration. The Id2 was computed as follows:

where, Id2 = slake durability index (second cycle), B = mass of oven-dried sample before the first cycle in gram, and W2 = mass of oven-dried sample retained after the second cycle, in grams. For assessing disintegration behavior, samples at two stages were tallied with Type 1, Type 2 and Type 3 patterns (ASTM D4644, 2008).

Sulphate Soundness Test

The sulphate soundness test was carried out on the aggregate samples to determine the durability of aggregate against physical weathering. The test was done as per the standard procedure of determining the sulphate soundness of aggregates (ASTM C88-05, 2005). The test sample of two kg of the size 50 mm down to 37.5 mm was prepared and was washed with distilled water and then oven dried at 105~110°C. A saturated solution of magnesium sulphate having a density 1.292 ± 0.008 g/mL was subjected to 48 hour immersion and drying cycles in which they were immersed in the saturated solution for 16~18 hours after being drained for two hours and then oven dried at 105°C for 24 hour and cooled for five hours at lab temperature. The sulphate soundness value (SSV) expressed in percentage was calculated as:

where, W1 is the initial weight of sample (kg) and W2 is the weight of the sample after five cycles.

Los Angeles Abrasion Test

Los Angeles Abrasion (LAA) test measures the resistance of aggregates to abrasion and impact and is an indirect test of the hardness of rock. The test was carried out in LAA machine (ASTM C535-09, 2009). To conduct the LAA test, the Grade A test sample that constituted of 5 kg mass of aggregate of 50 mm down to 37.5 mm size and 37.5 mm down to 25 mm size was prepared and was placed in the LAA machine along with 12 steel balls. The machine was set to revolve for 1,000 revolutions. After completion of revolutions, the steel bass was taken out, and the sample was placed in a tray and was sieved at 1.7 mm sieve. The retained sample was weighed. The LAA value was calculated using the following expression. The following formula was used to calculate the abrasion loss in percentage:

where, W1 is an initial weight of the sample and W2 is the weight of the sample retained on 1.7 mm sieve.

Result and Discussion

Description and Classification of Samples

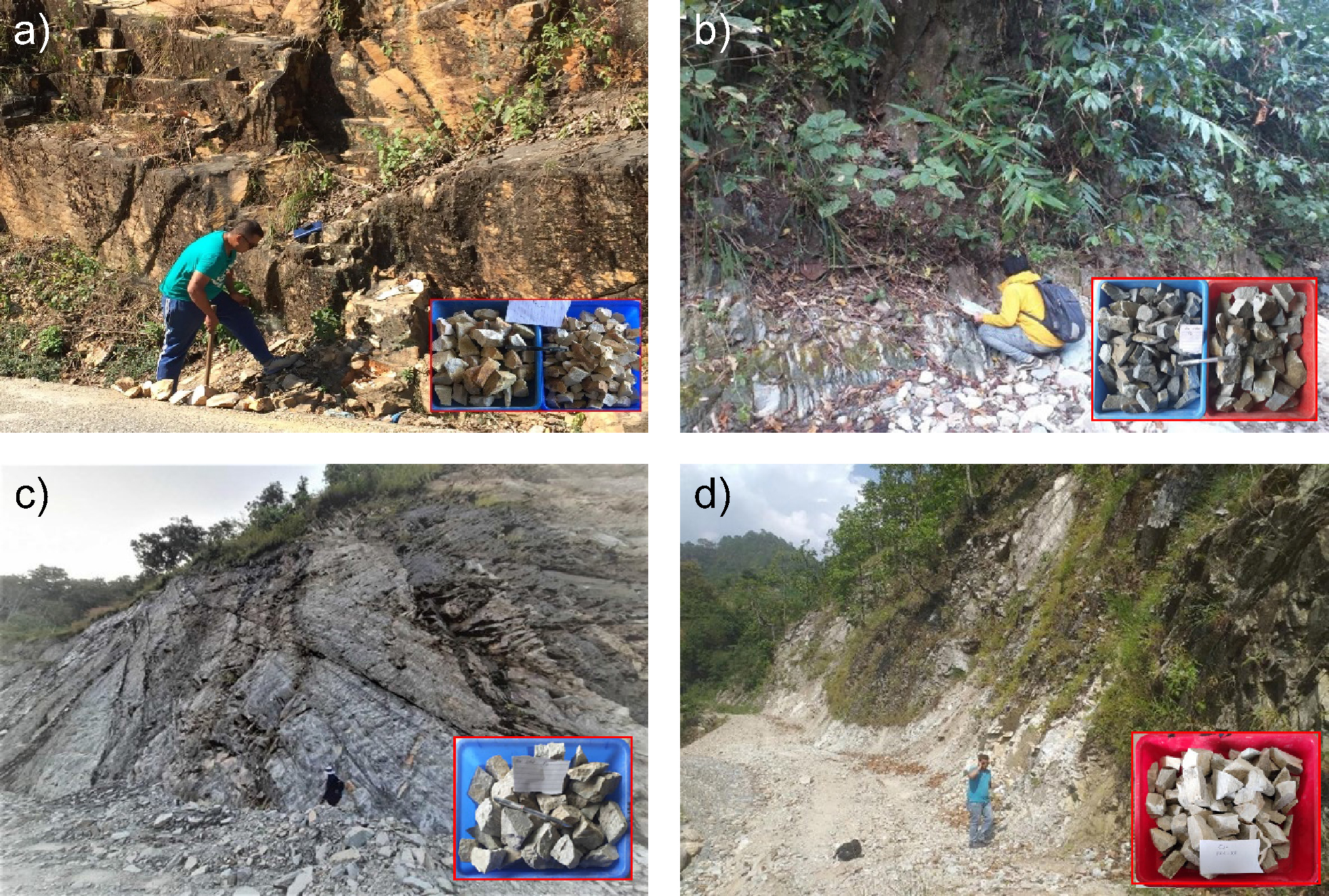

The Fagfog Quartzite (Fig. 2a) samples, collected from bedrock, are all medium-grained monomictic quartzite of the Precambrian age (Stöcklin and Bhattarai, 1977) and the total 15 samples were analyzed from this unit (Fig. 3a and 3b). They have a nominal size of 37.5 mm, a very angular, bladed to prolate particle shape, and a rough surface texture (Table 2). The samples display white to yellowish or brownish-white colors, with no coating or extraneous materials observed. These samples are classified as crushed quartzites, resulting from the crushing of large fragments obtained from the bedrock.

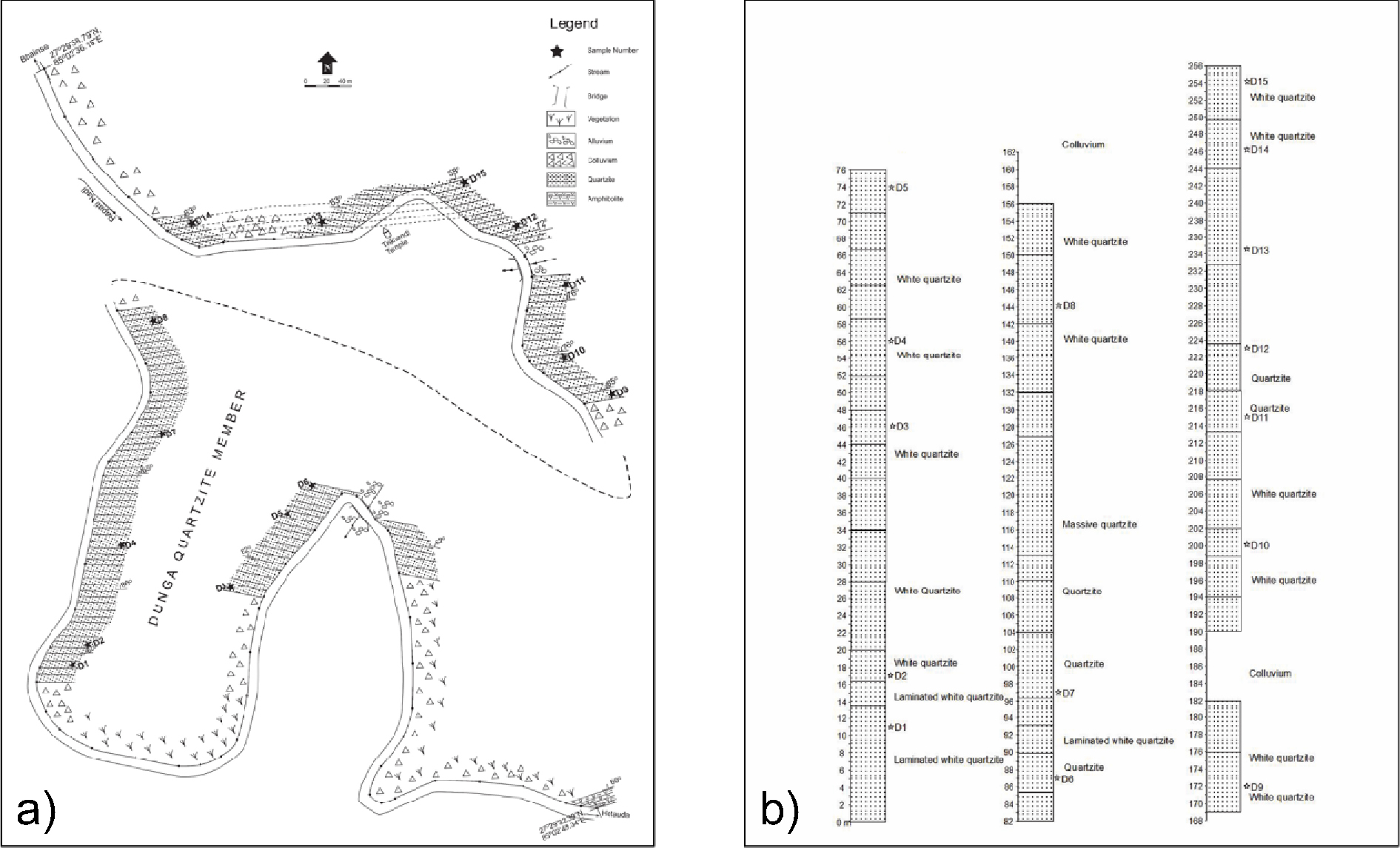

Similarly, the Dunga Quartzite (Fig. 2b) samples, collected from bedrock are all crushed rock with a nominal size of 37.5 mm (Table 2). The total 15 samples collected from various horizons (Fig. 4a and 4b), exhibit a rough surface texture and vary in color, including shades of grey, light grey, and milky white. No coating or extraneous materials are present. Petrologically, these samples are classified as monomictic quartzite and belong to the pre-Cambrian age. The quartzite samples exhibit either well-banded or massive structures, with some samples showing crude banding.

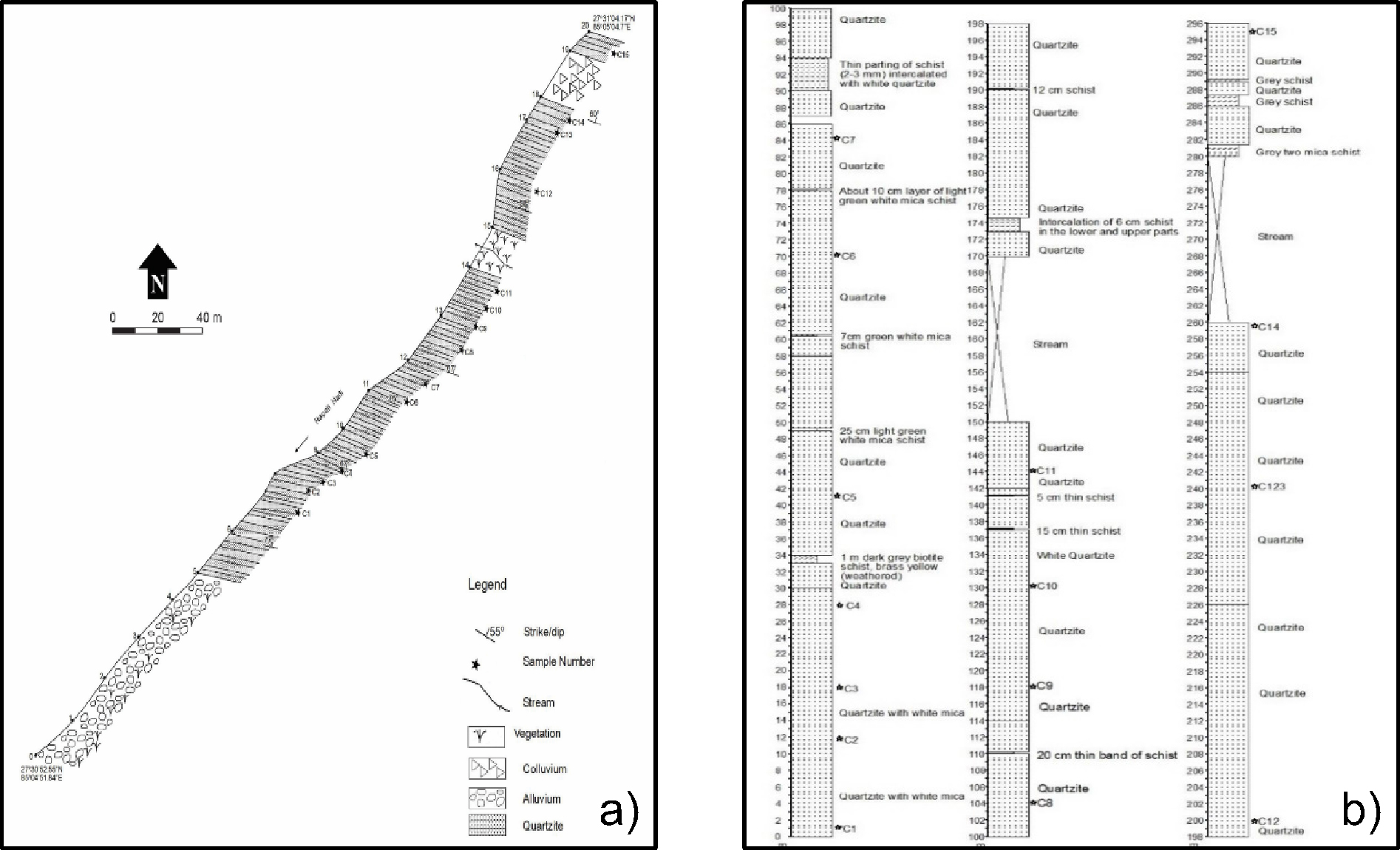

In the case of the quartzite samples collected from the Pandrang Quartzite (Fig. 2c, Fig. 5a and 5b) and Chisapani Quartzite (Fig. 2d, Fig. 6a and 6b) both crushed rocks sourced from bedrock. They have a nominal size of 37.5 mm, a rough surface texture, and a very angular, bladed to prolate particle shape (Table 3). The samples exhibit white to yellowish or brownish-white colors, with no coating or extraneous materials present. These samples are classified as monomictic quartzite and belong to the Precambrian age.

Table 2.

Physical characteristic of Fagfog, Dunga, Chisapani and Pandrang Quartzite

Fig. 5.

a) A route map showing lithology of the Pandrang Quartzite of the Kalitar Formation and the sampling sites, b) A graphic log of the Pandrang Quartzite exposed in the uphill side of the Tribhuvan Highway between Hetauda and Bhanse, showing lithology and sample horizons. The P denotes the sample numbers.

Table 3.

Flakiness and elongation indices of quartzite ballasts

Physical Properties

Shape Indices

Flakiness and Elongation Indices were determined and listed for quartzite aggregates of each of the samples (Table 4). Flakiness is the percentage by weight of particles, whose thickness is less than 0.6 times the average size of the particles between passing and retained sieves (BS, 1989). For Fagfog Quartzite, the Flakiness Index ranges between 0.92% (in F2) and 8.80% (in F13) (Table 4). The Flakiness index remains approximately below 9% which indicates quartzites are strongly interlocked, and not influenced by structure. Elongation Index is the percentage by weight of particles whose length is greater than 1.8 times the average size of the particles between passing and retained sieves (BS, 1989) and the Fagfog Quartzite yielded the value between 26.33% (F11) and 56.68% (in F2).

The Dunga Quartzite aggregates showed varying values of flakiness and elongation. The Flakiness Index (FI) ranged from 0.00% to 10.71%, with D4 having the lowest FI and D15 having the highest (Table 3). This indicates the presence of flaky particles in the aggregates, with aggregates having lower FI values being more desirable for better particle shape and angularity. The Elongation Index (EI) ranged from 17.00% to 84.55%, with D8 having the lowest EI and D14 having the highest (Table 3). Higher EI values indicate a larger proportion of elongated particles in the aggregates, which may affect compactness and interlocking.

The shape indices, specifically the Flakiness Index (FI) and Elongation Index (EI), were tested for the Pandrang and Chisapani Quartzite samples. The FI measures the percentage of flat and elongated particles, while the EI measures the percentage of elongated particles (BS, 1989). For the Pandrang Quartzite samples, the FI ranged from 2.30% to 7.97%, with an average of 4.75% (Table 3). The EI ranged from 23.0% to 65.37%, with an average of 41.98%. For the Chisapani Quartzite samples, the FI ranged from 1.03% to 11.26%, with an average of 5.23% (Table 3). The EI ranged from 27.54% to 69.14%, with an average of 47.45% (Table 4). In general, lower FI percentages and higher EI percentages indicate more desirable aggregate shapes.

All the study units exhibit varying shape indices that provide insights into their particle morphology. The Fagfog Quartzite shows relatively low flakiness and a range of elongation values, while Dunga Quartzite demonstrates flakiness and elongation variations. The Pandrang Quartzite and Chisapani Quartzite display moderate levels of flakiness and elongation. Lower flakiness and higher elongation percentages are generally preferred for better aggregate shapes.

Specific Gravity, Density and Water Absorption

Density does not rely on quartz content in this study which is opposed to the result of increasing density with an increased amount of quartz (Gupta and Sharma, 2012). The quartzites studied were of medium- to coarse-grained, sillimanite with a highly preferred orientation of grains. Water absorption determines the ability of an aggregate to absorb water in the moist environment and indicates the connectivity of voids from the surface inwards of the particles.

The specific gravity (relative density) for the Fagfog Quartzite ranged from 2.38 to 2.70, with density variations in the oven-dried state falling within a narrow range (Table 4). The water absorption values ranged from 0% to 2.50%, with four samples showing water absorption of more than 1% (Table 4). It is worth noting that sample F12 showed the highest water absorption despite having a high apparent density, possibly due to the presence of connected pores around the particles.

Regarding Dunga Quartzite, the relative density (specific gravity) values ranged from 2.27 to 2.68, while the Apparent Specific Gravity (ARD) values ranged from 2.28 to 2.70 (Table 4). The oven-dry density (OD) values ranged from 2,249.92 Kg/m3 to 2,662.16 Kg/m3, and the saturated surface dry (SSD) density values ranged from 2,261.00 Kg/m3 to 2,675.11 Kg/m3 (Table 4). The apparent density values ranged from 2,275.20 Kg/m3 to 2,697.19 Kg/m3. The water absorption values for Dunga Quartzite ranged from 0.24% to 0.74% (Table 4).

In the case of Pandrang Quartzite, the apparent specific gravity (ARD) values ranged from 2,487.59 Kg/m3 to 2,697.19 Kg/m3, with an average of 2,582.92 Kg/m3 (Table 4). The oven-dry density (OD) ranged from 2,566.82 Kg/m3 to 2,692.60 Kg/m3, averaging at 2,628.25 Kg/m3. The SSD density varied between 2,611.29 Kg/m3 and 2,697.19 kg/m3, with an average of 2,657.89 Kg/m3. The water absorption values ranged from 0.24% to 0.74% (Table 4).

For Chisapani Quartzite, the oven-dry densities ranged from 2,521.29 Kg/m3 to 2,733.15 Kg/m3, SSD densities ranged from 2,560.46 Kg/m3 to 2,751.49 Kg/m3, and apparent densities ranged from 2,505.77 kg/m3 to 2,739.80 Kg/m3 (Table 4). The relative densities (specific gravity) ranged from 2.53 to 2.75, with an average of 2.64. The water absorption values ranged from 0.24% to 1.00%.

Overall, the quartzite samples from all four types showed relatively narrow ranges in density values and water absorption, indicating consistent physical properties and similar porosity levels.

Table 4.

Results of density, specific gravity and water absorption of quartzite ballasts

Bulk Density

Bulk density includes both void spaces among aggregate particles and the density contributed by particles. The bulk density values for Fagfog Quartzite range from 1,203.62 Kg/m3 to 1,386.88 Kg/m3 (Table 5). In comparison, the Dunga Quartzite samples have bulk density values ranging from 1,165.16 kg/m3 to 1,436.65 Kg/m3 while the Chisapani Quartzite samples exhibit a range of bulk density values from 1,260.18 Kg/m3 to 1,441.18 Kg/m3 (Table 5). The Pandrang Quartzite samples have bulk density values ranging from 1,151.58 Kg/m3 to 1,348.42 Kg/m3 (Table 5). Higher bulk density values generally indicate a denser particle arrangement and a lower percentage of voids, suggesting a more compact and less porous structure. On the other hand, lower bulk density values tend to correspond to higher percentages of voids, indicating a looser and more porous structure. Overall, these variations in bulk density provide insights into the density and porosity characteristics of each quartzite type, showing their physical properties.

Table 5.

Bulk density and %void of quartzite ballasts

Mechanical Properties

Point Load Strength Index

The point load strength index (PLSI) determines the strength index value at the given point. Fagfog Quartzite showed the lowest PLSI range of 2.40 to 11.45 MPa (Table 6). However, it should be noted that the corresponding uniaxial compressive strength (UCS) derived from empirical relations for Fagfog Quartzite ranged from 39 MPa to 302 MPa (Table 6), indicating a wide variability in strength. Dunga Quartzite samples displayed a broader range of average diameters and load values compared to Fagfog Quartzite. The UCS values for Dunga Quartzite ranged from 94 MPa to 297 MPa (Table 6), suggesting a higher overall strength compared to Fagfog Quartzite. Pandrang Quartzite samples have higher UCS values ranging from 207 MPa to 70 MPa (Table 6), classifying them as “Very Strong” and “Strong”. This indicates a generally higher strength compared to both Fagfog and Dunga Quartzite samples. In terms of strength classification, Chisapani Quartzite showed the highest average PLSI of 40.6 MPa, categorized as “Extremely Strong”. Multiple samples of Chisapani Quartzite were classified as “Very Strong”, “Strong”, or “Medium Strong”, suggesting a relatively consistent and high level of compressive strength.

Overall, when comparing the four quartzite samples, Pandrang Quartzite and Chisapani Quartzite showcased higher strength characteristics compared to Fagfog and Dunga Quartzite. Pandrang Quartzite showed high UCS values, while Chisapani Quartzite displayed the highest average point load strength index and a consistent classification of “Extremely Strong”.

Table 6.

Results of Point-load strength index of quartzite aggregate

Aggregate Impact Value and Aggregate crushing value

The Aggregate impact value (AIV) is a measure of resistance to sudden impact, which may differ from its resistance to gradually applied compressive load. In short it measures the toughness of the aggregate. The AIV and ACV tests conducted on samples of Fagfog, Dunga, Pandrang, and Chisapani Quartzite provide insights into their resistance to impact and crushing forces. Fagfog Quartzite exhibits AIV values ranging from 14.85% to 21.57% and ACV values ranging from 15.51% to 29.70% (Table 7). Dunga Quartzite shows AIV percentages from 9.71% to 28.16% and ACV percentages from 18.14% to 31.30% (Table 7). Pandrang Quartzite presents AIV values from 12.62% to 24.27% and ACV values from 21.33% to 29.62% (Table 7). Chisapani Quartzite displays AIV values from 13.86% to 33.98% and ACV values from 21.36% to 29.63% (Table 7). These results indicate variations in the strength and durability of the quartzite samples, with lower AIV and ACV values indicating higher resistance to impact and crushing forces, respectively. Overall, these findings showed the quality and suitability of the quartzite.

Table 7.

Results of aggregate impact test of the quartzite aggregate

Durability

Three durability attributes, i.e., slake durability index (Id2), Sulphate Soundness Value (SSV) and Los Angeles Abrasion Value (LAAV) have been determined to assess the durability of quartzites.

Slake Durability Index

Five-cycle slake durability test was conducted to obtain a precise result instead of two-cycle test to obtain the deterioration character of rocks under more cycles. The Fagfog, Dunga, Pandrang, and Chisapani Quartzites were evaluated for their durability and resistance to weathering through various tests. For Fagfog Quartzite, the slake durability index (Id2) ranged from 96.94% to 100% (Table 8), indicating high to very high durability against slaking. The slake durability index after the fifth cycle (Id5) ranged from 95.1% to 99.11%, with a slight decrease observed between the second and fifth cycles. Some samples exhibited type I deterioration, while others showed type II deterioration. Type I deterioration is characterized by the breaking down of rock particles into smaller fragments due to the physical forces exerted during the test. This mode of deterioration occurs when the particles experience internal stress and break apart. Type I deterioration is typically associated with rocks that have weak bonding between their constituent grains or have inherent weakness within their structure. It indicates a lower resistance to disintegration and suggests that the rock may be prone to crumbling or breaking down when subjected to wetting and drying cycles in natural or engineering environments.

Type II deterioration, on the other hand, involves the gradual erosion or removal of fine particles from the surface of rock samples due to the mechanical action of water during the test. This mode of deterioration occurs when the rock particles are relatively stable and resist internal breakage but are susceptible to surface erosion. Type II deterioration suggests that while the rock may not break apart easily, it may experience surface erosion or wear when exposed to water-related processes, such as rain or wave action.

Both Type I and Type II deterioration observed in the Slake Durability Test provide insights into the rock’s behavior and its resistance to disintegration under wetting and drying conditions.

Dunga Quartzite experienced weight loss after five cycles, ranging from 97.09% to 100.00% (Table 8) further suggesting varying degrees of weathering and weight loss, indicating differences in resistance to weathering among the samples. The Pandrang Quartzite demonstrated excellent durability with minimal weight changes after each cycle, ranging from 99.01% to 100.00%, while. The value in Chisapani Quartzite ranges from 97.20% to 100.00% after the fifth cycle, with some samples showing zero weight loss.

Table 8.

Results of slake durability index of quartzite ballasts

*Gambles Slake Durability Classification (Goodman, 1980): Id2nd: >98% very high durability; 95~98% high durability; 85~95 medium high durability; 60~85 medium durability; 30~60 low durability; <30 very low durability.

Los Angeles Abrasion Value

The Los Angeles Abrasion (LAA) test determines the hardness property of aggregates. It measures the abrasion resistance of aggregates (ASTM C535-09, 2009). All the quartzite particles tested were of angular to subangular shape because all the samples were crushed aggregate. Therefore, the angular shape does not indicate much bearing on Los Angeles Abrasion Value (LAAV).

The Fagfog Quartzite, only one out of fifteen samples, F2, exceeded the threshold of 30%. Furthermore, seven samples had LAAV values below 25%, with four of them even below 20% (Table 9). This suggests that most of the Fagfog Quartzite samples display favorable resistance to abrasion. For the Dunga Quartzite, the LAAV values ranged from 15.42% to 31.32% with an average of 22.36%. Sample D13 exhibited the lowest LAAV at 14.89%, indicating a relatively higher abrasion resistance, while sample D7 had the highest LAAV at 31.32%, suggesting a lower resistance (Table 9). For Pandrang Quartzite, the loss of weight due to hardness testing ranged from 22.78% to 37.17%, with an average of 28.83% (Table 9). The majority of the Quartzite aggregates showed high hardness and abrasion resistance. Lastly, the Chisapani Quartzite samples had LAAV values ranging from 22.35% to 48.63% (Table 9). Samples C4 and C9 showed the lowest LAAV values, indicating higher abrasion resistance, while samples C12 and C15 had the highest LAAV values, suggesting lower resistance.

Table 9.

Results of loss angeles abrasion of quartzite ballasts

Sulphate Soundness Value

The Sulphate Soundness is a cyclical test that evaluates aggregates for durability and resistance to degradation from weather cycles. The Sulphate Soundness Value (SSV) values for the Fagfog Quartzite range from 0.20% to 4.59%, with most samples falling between 1% and 5% (Table 10). Despite these variations, the obtained SSV values are remarkably low, indicating a high level of durability for the quartzite. Similarly, the Dunga Quartzite samples display SSV values ranging from 0.00% to 0.48% (Table 10), showing good resistance to deterioration and weathering. The Pandrang Quartzite exhibits very low SSV values, indicating its high quality and resistance to weathering caused by freeze and thaw cycles. Lastly, the Chisapani Quartzite samples demonstrate varying SSV percentages, with sample C8 having the highest value at 0.24% and several samples showing SSV values of 0% with an average 0.09% (Table 10).

Table 10.

Result of magnesium sulphate soundness test of quartzite ballasts

Among the four quartzite units’ samples, Fagfog Quartzite showed a moderate proportion of elongated particles, with an EI ranging from 28.85% to 56.68%. It also has a relatively low FI of 0.92 to 8.80%, indicating a lower presence of flat and elongated particles. The ACV ranges from 15.51% to 29.70%, suggesting a moderate resistance to crushing, and the AIV ranges from 14.85% to 22.77%, indicating a moderate resistance to sudden impacts. Fagfog Quartzite has a specific gravity of 2.33 to 2.64, low water absorption (%WA) of 0.00 to 2.50%, and a bulk density of 1,223.98 to 1,386.88 kg/m3. Its point load strength index (Is(50)) ranges from 62 to 302 MPa, and it shows good slake durability (95.19% to 99.11%). The LAAV ranges from 12.07% to 31.34%, indicating moderate resistance to abrasion, and the sulfate soundness value ranges from 0.20% to 4.59%, indicating good resistance to sulfate attack.

Dunga Quartzite displays a similar proportion of elongated particles, with an EI range of 33.28% to 63.74%. Its FI ranges from 0 to 9.42%, suggesting a similar presence of flaky particles as Fagfog Quartzite. The ACV ranges from 18.14% to 31.30%, indicating relatively higher resistance to crushing compared to Fagfog Quartzite. The AIV ranges from 9.71% to 28.16%, suggesting a variable resistance to sudden impacts. Dunga Quartzite has a specific gravity of 2.27 to 2.65, a slightly higher %WA of 0.25% to 0.74%, and a bulk density of 1,165.16 to 1,436.65 kg/m3. It Is(50) ranges from 94 to 297 MPa, and it show high slake durability (98.06% to 100%). The LAV ranges from 14.89% to 31.32% and sulphate soundness value ranges from 0 to 0.48% which shows the ability of aggregates to resist weathering and abrasion since these values lie within the international specifications, the aggregates are suitable for various uses as; both asphaltic and concrete aggregates.

The Pandrang Quartzite showed a higher proportion of elongated particles, with an EI range of 37% to 65%. Its FI ranges from 0% to 7.58%, indicating a relatively lower presence of flaky particles. The ACV ranges from 21.33% to 29.62%, indicating a moderate resistance to crushing, and the AIV ranges from 12.62% to 24.27%, indicating a moderate resistance to sudden impacts. The Pandrang Quartzite has a specific gravity of 2.54 to 2.70, a %WA of 0.24% to 0.74%, and a bulk density of 1,151.58 to 1,371.04 kg/m3. It Is(50) ranges from 72 to 207 MPa, and it show high slake durability (98.17% to 100%). The LAV ranges from 21.33% to 29.62%, and the sulfate soundness value ranges from 0 to 0.48% which shows the ability of aggregates to resist weathering and abrasion since these values lie within the international specifications, the aggregates are suitable for various uses as; both asphaltic and concrete aggregates.

The Chisapani Quartzite shows a lower proportion of elongated particles, with an EI range of 1.03% to 11.26%. However, it has a significantly higher presence of flaky particles, with an FI range of 27.54% to 69.14%. The ACV ranges from 21.36% to 29.63%, indicating a similar resistance to crushing as Pandrang Quartzite. The AIV ranges from 13.86% to 33.98%, suggesting a variable resistance to sudden impacts. Chisapani Quartzite has a specific gravity of 2.53 to 2.75, a %WA of 0.24% to 1.00%, and a bulk density of 1,260.18 to 1,441.18 kg/m3. Its Is(50) ranges from 18.7 to 70.2 MPa, and it shows high slake durability (97.20% to 100%). The LAV ranges from 22.35% to 48.63%, and the sulfate soundness value ranges from 0 to 0.24% showing the ability of aggregates to resist weathering and abrasion.

In summary, Fagfog Quartzite and Dunga Quartzite have similar characteristics. The Fagfog Quartzite generally shows slightly better values for elongation index, flakiness index, and water absorption. The Pandrang Quartzite shows a higher proportion of elongated particles but has lower flakiness index values compared to Fagfog and Dunga Quartzite. The Chisapani Quartzite stands out with its significantly higher presence of flaky particles and lower elongation index values. Mechanical properties and durability characteristics also vary among the samples, with Fagfog and Dunga Quartzite generally showing higher strength and better resistance to abrasion and sulfate attack.

Comparison among quartzites of previous and present studies

Abdullah and Singh (2010) reported a density of 2,677 kg/m3, Gupta and Sharma (2012) provided values of 2,710 kg/m3, 2,660 kg/m3, and 2,690 kg/m3, while the present study reported a range of 2,641 kg/m3 to 2,732 kg/m3, with specific values for Fagfog, Dunga, Pandrang, and Chisapani Quartzites respectively. Other studies (Abdullah and Singh, 2010; Gupta and Sharma, 2012; Paudel and Tamrakar, 2012; Adom-Asamoah et al., 2014; Bista and Tamrakar, 2015; Maharjan, 2015; Singh et al., 2017) also presented different density values, such as 2,560 kg/m3, 2,590 kg/m3, and a range of 2,640 kg/m3 to 2,730 kg/m3. The present study density ranges of 2,570 kg/m3 to 2,770 kg/m3, 2,680 kg/m3 to 2,812 kg/m3. The specific gravity of four quartzite units’ ranges between 2.66 and 2.65 (Table 11) that is identical to the study by Gupta and Sharma (2012) stated a specific gravity value of 2.77.

Paudel and Tamrakar (2012) mentioned water absorption in a range of 1.0% to 2.0%, while the present study reported a range of 0.32% to 0.9% for four Quartzite unit (Table 11). Bulk density values obtained in the present study as 1,165.16 kg/m3 to 1,436.65 kg/m3 (Table 11) is within a range of the results provided by Shareef et al. (2015) i.e., 1,204 kg/m3 to 1,387 kg/m3, and Bista and Tamrakar (2015) also mentioned a range of 1,260.18 kg/m3 to 1,441.18 kg/m3. Individually, among the four, the Chispani Quartzite showcases the highest bulk density range, indicating a relatively higher density compared to the other types. The Chisapani Quartzite is composed of quartz, which has a density of around 2,650 kg/m³ i.e., higher quartz content (Table 11).

Table 11.

Comparison of physical, mechanical and durability properties of the quartzite units of Central Nepal Lesser Himalaya with various standards

Regarding the Unixial compressive strength (UCS) values it varied across the studies as well. The present study obtained a range of 94 MPa to 297 MPa (Table 11). Other studies (Abdullah and Singh, 2010; Gupta and Sharma, 2012; Paudel and Tamrakar, 2012; Adom-Asamoah et al., 2014; Bista and Tamrakar, 2015; Singh et al., 2017) provided different ranges and specific values, such as 18.7 MPa to 70.2 MPa, 39 MPa to 302 MPa, and 70 MPa to 207 MPa. Despite the Dunga Quartzite displays the highest range of unconfined compressive strength, indicating its overall superior strength as compared to the other three.

The present study reported AIV values ranging from 9.71% to 28.16% and ACV values ranging from 18.14% to 31.30% (Table 11). The present study reports a density range of 2,641 kg/m3 to 2,732 kg/m3 (Table 11) and these results is identical to the past studies (Abdullah and Singh, 2010; Gupta and Sharma, 2012). The specific gravity values reported in the present study range from 2.57 to 2.70 and 2.68 to 2.81 (Table 11). Gupta and Sharma (2012) reported a specific gravity of 2.77 and the values does not significantly deviate from the reported range in other studies.

The present study reports a water absorption range of 0.32% to 0.9% (Table 11), while Paudel and Tamrakar (2012) mention a range of 1.0% to 2.0%. Lower water absorption is generally preferable, indicating better resistance to moisture-related issues. The bulk density ranges from 1,165.16 kg/m3 to 1,436.65 kg/m3 in the four Quartzite units which is similar to the results from Shareef et al. (2015) and Bista and Tamrakar (2015). However, the Chispani Quartzite exhibits the highest range of water absorption, implying its potential to absorb more water compared to the others.

Impact Value (AIV) and Aggregate Crushing Value (ACV) ranging from 9.71% to 28.16% and 18.14% to 31.30% (Table 11). Lower values of AIV and ACV are generally preferred, indicating better resistance to impact and crushing. Dunga Quartzite exhibits the highest range of elongation resistance, indicating its ability to withstand deformation compared to the other types. Fagfog and Chispani Quartzite also display relatively higher elongation resistance. Chispani Quartzite has the widest range of flakiness index, suggesting a potential for lower quality due to increased flakiness compared to the other types. All four types fall within a similar density range, with no significant differences observed among them. Considering these properties, Dunga Quartzite stands out for its higher elongation resistance, superior point load strength, and unconfined compressive strength.

The best quartzite for a particular application will depend on the specific requirements of that application. However, based on the properties listed above, Chispani quartzite is generally considered to be the best for ballast aggregates. It has the highest UCS, AIV, and ACV values, which means that it is the strongest and most wear-resistant of the four. It also has a relatively low WA value, which means that it is not as susceptible to water damage. Fagfog Quartzite is also a good choice, as it has high UCS and AIV values. However, it has a higher WA value than Chispani quartzite, so it may be also high.

Conclusions

The aggregates of quartzite within the Central Himalaya show varying levels of flakiness and elongation. Similarly, the quartzite of studied litho-units has uniform physical properties and porosity levels. Regarding the bulk density values, all four quartzites yielded variations in particle arrangement, porosity, and density that indicate the distinct physical characteristics of each quartzite unit. Pandrang and Chisapani Quartzite have shown higher strength characteristics as compared to Fagfog and Dunga Quartzite. Both the AIV and ACV test results have shown a varying level of resistance to impact and crushing forces and most of them have higher values indicating their better suitability and quality. In the context of slake durability index tests, the Fagfog Quartzite shows high to very high durability against slaking, with a slight decrease in durability observed after the fifth cycle. Dunga Quartzite shows varying degrees of weathering and weight loss, while Pandrang and Chisapani Quartzite have durability with minimal weight changes, making their strong resistance to weathering. The Magnesium sulphate soundness tests also indicate that the quartzite within the Central Himalaya yields high durability and resistance to degradation caused by weather cycles.

In conclusion, the comparison between the quartzites investigated in previous studies and the present study shows that the quartzite within the Central Himalaya is appropriate for specific applications, considering their unique properties and variations, and among the four Quartzite units, the Chisapani Quartzite is the best whereas the Fagfog Quartzite is the alternative for the aggregate.